When I finally sat down to list out the products we've built and deployed for customers over the years, it really hit me: this isn't just "tech".

These are systems that decide whether people go home safely, whether quality issues are caught before they become recalls, and whether operations run with confidence instead of guesswork.

For us, safety, quality and process performance aren't separate conversations – they're tightly connected. Every incident avoided, every defect caught early and every process made more reliable has a real human and commercial impact.

Below are just some of the ways we've been helping customers do that.

1. Dragline Proximity Detection – Integrated With the Braking System

We developed and deployed an award-winning Dragline Proximity Awareness System that does more than just warn operators – currently deployed at Coronado and BMA.

In a world-first, we integrated the system directly into the braking system so that when high-risk proximity is detected, the machine doesn't just beep – it slows and stops to prevent accidents from occurring in the first place.

For teams working around massive, unforgiving equipment, that's the difference between a near miss and a life-changing incident.

2. Dozer & Excavator Edge and Void Detection

Working near highwalls, drop-offs and underground voids comes with constant risk. Operators are often making decisions with limited visibility, especially in poor light or dusty conditions.

Our Dozer & Excavator Edge and Void Detection systems use LiDAR sensing and analytics to detect hazardous edges and voids in real time and warn operators before they reach the point of no return.

The goal is simple: reduce the chance of rollovers, wall failures and unstable ground events while letting operators focus on doing their job confidently.

3. Forklift, Truck, Vehicle & Pedestrian Detection

In logistics and manufacturing, people and machines are sharing tighter and busier spaces than ever. High-visibility vests and painted walkways help – but they're not enough on their own.

We've deployed Forklift, Truck, Vehicle and Pedestrian Detection and Warning Systems that:

The outcome is fewer blind spots, fewer close calls, and a culture where safety isn't left to chance or "good luck on the day".

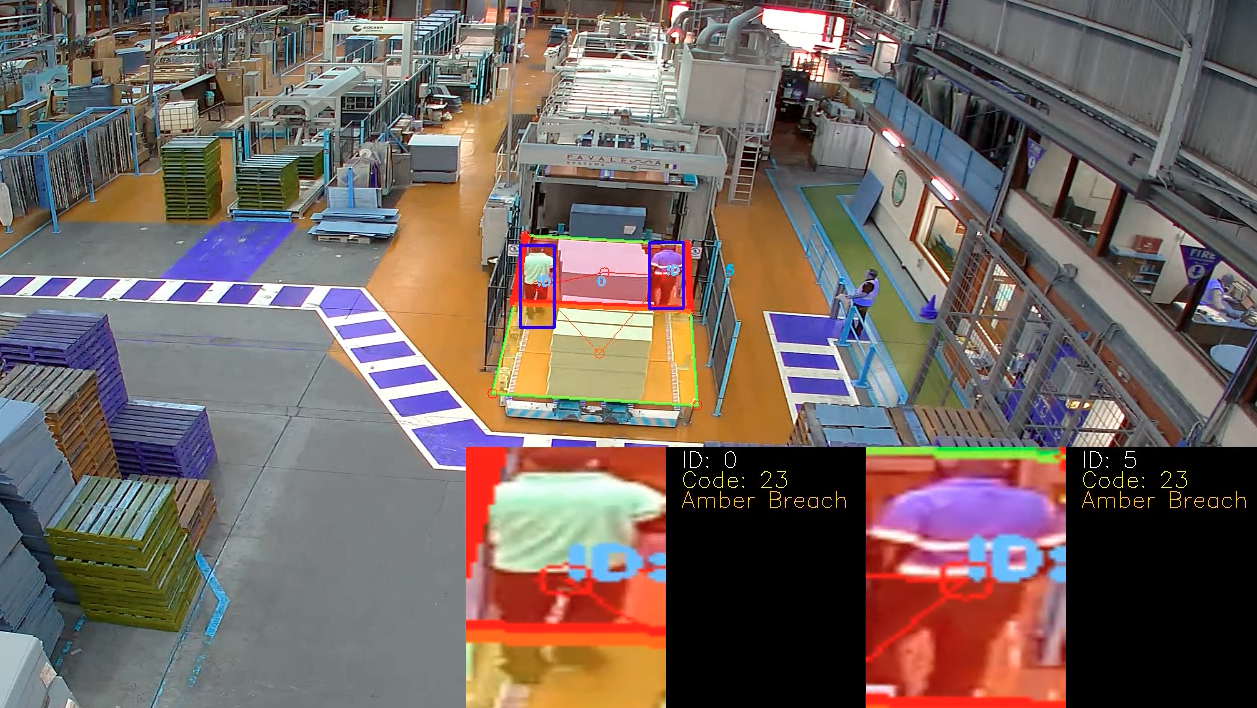

4. Dynamic Safety Zones Around Dangerous Machinery

Some machines simply cannot be approached while in motion.

We've built Dynamic Safety Zones around dangerous machinery, fully integrated into the PLC of the machine. If a person or vehicle breaches that zone, the system automatically triggers a response – up to and including instantly stopping the machine.

Instead of relying on someone noticing a breach and hitting the emergency stop in time, the system reacts in milliseconds.

5. Biscuit Anomaly & Foreign Body Detection

On production lines, small quality issues can quickly turn into big product losses or recalls.

We built Biscuit Anomaly & Foreign Body Detection on conveyor belts – a solution that can be applied to all food types to detect:

All of this happens in real time, as the product flows down the line, allowing operators to act immediately instead of discovering the issue at the end of the run (or worse, in the hands of a customer).

6. Pallet & Product Quality Defect Detection

Warehouses and distribution centres ship thousands of pallets a day. A damaged pallet or poorly strapped load isn't just an eyesore – it's a safety risk and a cost issue.

Our Pallet & Product Quality Defect Detection solutions automatically identify:

By catching these issues before goods leave the facility, companies reduce damage claims and rework.

7. Precious Material Grading Systems

In operations dealing with high-value or precious materials, every small improvement in grading accuracy matters.

We're developing Precious Material Grading Systems that help customers:

The result is improved yield, better reporting and a more consistent approach in both the quality and valuation of material being processed.

8. AI-Powered Quality Assurance in Document Scanning

We've applied AI-powered Quality Assurance to high-volume document scanning workflows to automatically detect:

This reduces manual checking, cuts down on rework and ensures that the digital records organisations rely on are accurate and complete.

Why This Matters

Looking back over this list, there's a common thread: none of these solutions started with "let's build some cool tech."

They started with real problems:

Technology came second. The business challenge came first.

If there's an area in your operation where safety, quality or process reliability keeps coming up in conversations – or keeps you up at night – there's probably a smarter, more robust way to handle it.

That's the space we love working in. Our capabilities and experience grows with every deployment.

Every one of these started with a real problem on a real site – an incident, a near miss, a quality failure, or a "we can't keep doing it this way" moment.

Let's Talk About Your Challenge

Book an appointment with us to discuss how we can help you.

Book a 30-Minute Call© Bigmate 2025